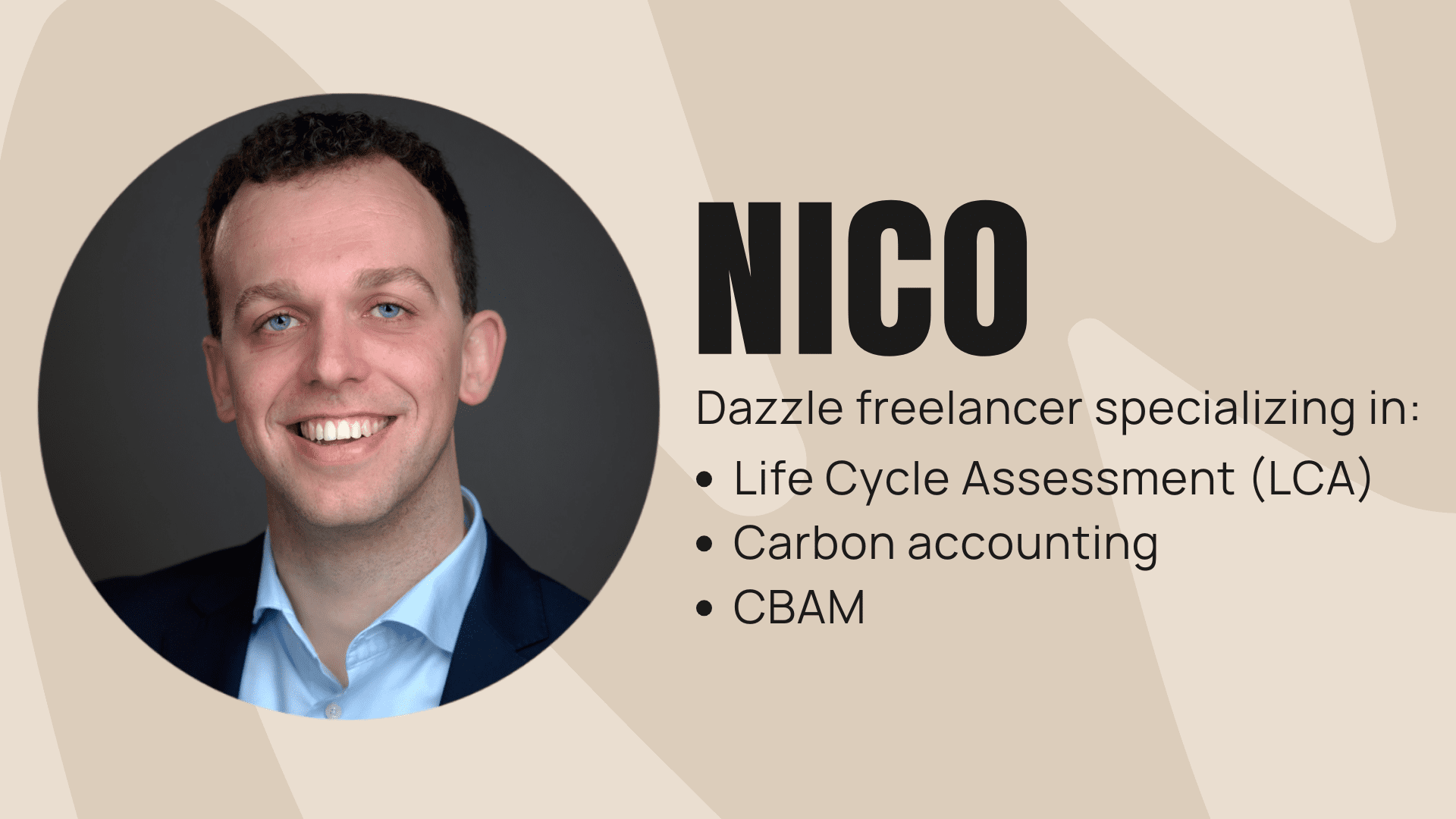

About the author

Nico van Eeden is a sustainability consultant specializing in Life Cycle Assessment (LCA), GHG-accounting, and project management. With a background in Industrial Ecology and experience managing organization-wide emission inventories and decarbonization projects across multiple industries, he helps organizations align their sustainability performance with global frameworks such as the GHG Protocol, SBTi, and ESG disclosure frameworks.

In recent years, Nico has led and advised projects involving Scope 1–3 carbon footprinting, LCAs, and emission reduction planning for multinational companies as well as major Dutch family businesses.

His goal is to support organizations in achieving transparent, credible, and actionable sustainability outcomes. He enables this by structuring data and workflows required for continuous monitoring and reporting.

If you feel you could use Nico’s expertise, contact Dazzle today, and we will put you in touch with him within 48 hours.

Truly understanding the environmental impact of your products starts with a Life Cycle Assessment (LCA), but getting it right isn’t always straightforward. Gathering accurate data, coordinating across departments, and interpreting results can quickly become overwhelming if you don’t have a clear approach.

To help you get started and avoid common pitfalls, in this guide, I’m sharing five practical tips to make LCAs manageable and actionable. These insights focus on starting smart, aligning teams, and building capability, so you can use LCAs to make better sustainability decisions without getting lost in the details.

1. Start small to build LCA experience

If you’re just beginning the LCA process, start with a small set of representative reference products.

This helps you understand the process, get familiar with the data requirements of your typical products, and prioritize those that matter most commercially.

2. Prepare a solid data strategy up front

LCAs have significant data needs, and it’s easy to underestimate them.

So make sure you create a clear data strategy early, and map LCA data requirements to existing ESG or business data processes so you can avoid duplication and gaps.

3. Align LCAs with other sustainability initiatives

LCA work often overlaps with other sustainability initiatives, like calculating your annual Scope 1–3 emissions.

When this is the case, it’s important to ensure that underlying assumptions and datasets are consistent across projects to maintain coherence and improve overall data quality.

4. Engage the right internal stakeholders early

LCAs are a joint effort, often involving data and knowledge/assumptions from procurement, facility, sales, and engineering teams.

This is especially true in cradle-to-gate analyses, where you track the product all the way to the customer and sometimes beyond. It is absolutely worth planning this stakeholder engagement upfront.

5. Decide on your software and resource approach

LCAs require dedicated software to carry out the calculations.

In practice, the first iterations of this work can be outsourced, and the capability to perform LCAs can then be gradually brought in-house — depending on your organization’s size and needs — both in terms of building internal expertise and investing in the necessary software and background databases.

Making LCAs work for your organization

LCAs don’t have to be a maze of data and calculations. With a structured approach, they become far more manageable, allowing you to get them right, so that they deliver meaningful insights into your products, support smarter decisions, and foster stronger collaboration across teams.

Progress comes from planning carefully, involving the right stakeholders early, and gradually building capability, transforming what can feel like a complex challenge into a manageable, repeatable process.